Seamech International provides design, engineering and testing services to the aerospace industry, both domestically and internationally. These services were expanded more than 15 years ago to include manufacturing and supply operations for specialty aviation products.

- Development

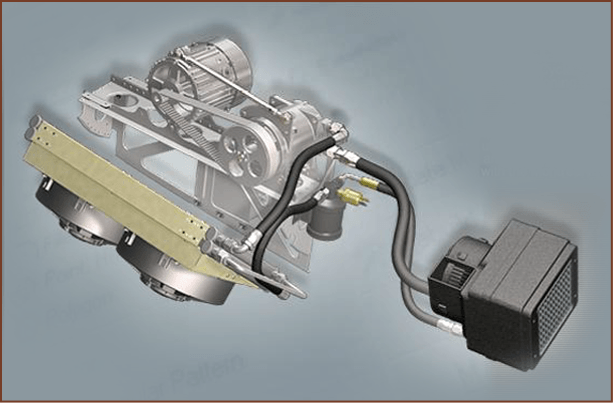

- Seamech has designed over 200 types of application specific vapor cycle air conditioning systems (VCS) and Environmental Control System (ECS) components for prototype, experimental, military, STC and TC aircraft programs

- Custom designed systems and components to fit customers’ specific requirements,when required

- Numerous off-the-shelf components available for system integration

- Engineering

- Autodesk Inventor Series 3D design software allows the 3D digital representation of components and tooling along with virtual simulation capability

- Automated generation of associative tooling design and machine code for manufacturing

- Testing

- Ability to “test drive” a system design through VCS and ECS laboratory evaluation by simulating aircraft cabin thermal loads: passenger, electrical, solar, convective and high temperature bleed-air

- Performance testing “pull-down” for air conditioning capacity design verification

- Durability testing through system cycling and timed operation to ensure the system meets performance goals through its design life.

- Reliability testing to avoid operational or performance interruptions during the life of the product by making required changes during the development phase, before customer deliveries begin

- Burst and proof pressures for refrigeration system components

- RTCA/DO-160 qualification testing done at approved laboratories for Seamech validation and certification credit with the FAA

- Quality Assurance

- AS9100 compliant

- Quality control inspection criteria developed jointly with customer

- Sampling inspection utilized as a means of acceptance for receiving incoming products

- Outgoing products receive a 100% visual and/or Acceptance Test Procedure (ATP) inspection